|

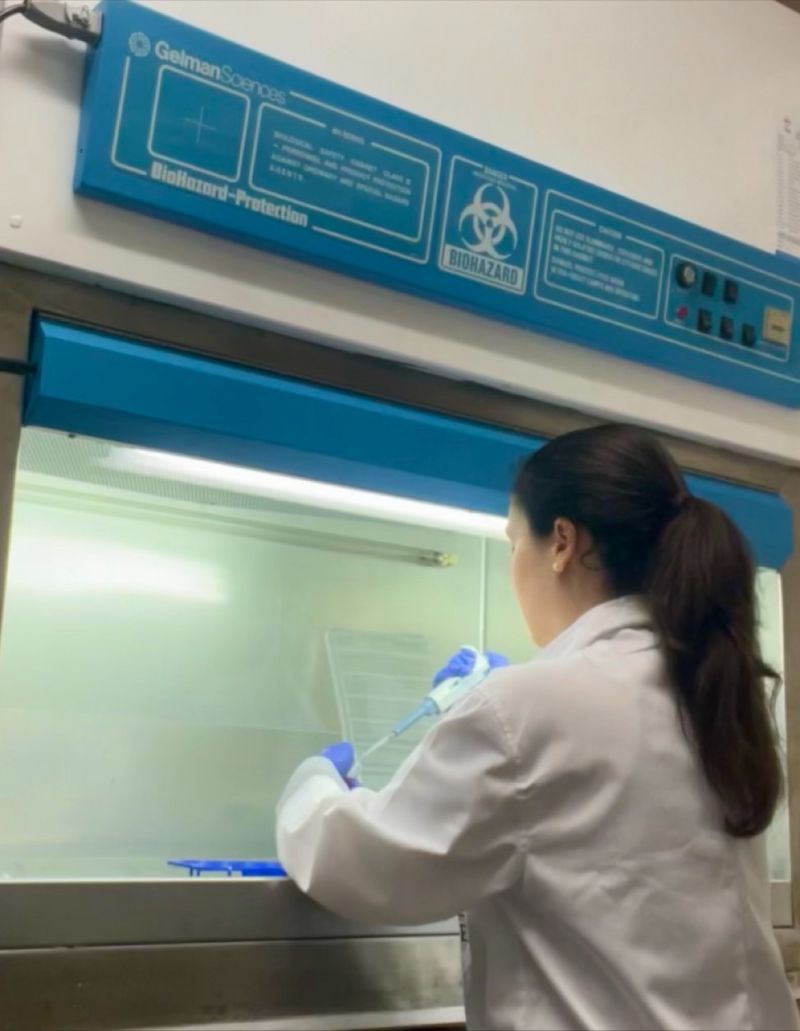

I built my own cell culture facility in order to complete the early-stage R&D necessary to start a biotech company. Here are the questions that land my inbox most weeks ⤵

Wait, you built your own lab? That’s crazy! How did you do that? ➡️ I previously built a lab while working at another early-stage startup. My husband had just finished building our house, so we figured a laboratory couldn’t be too much more challenging. ___ How much did it cost? ➡️ We spent ~14k USD (20k AUD) to establish the laboratory. It required some investment, but it was much less expensive than most people expect! Factors that helped us do a lot with a limited budget: 💵Performing some of the building work ourselves (e.g. dry wall) 💵Purchasing second-hand lab equipment 💵Claiming 43.5% of R&D spending back from the Australian government (very helpful!) ___ Why didn’t you just rent lab space? ➡ I live ~2 hours from Sydney. Because this is regional Australia, there are no rental lab facilities nearby. I wanted the lab nearby so R&D could happen seven days a week. ____ Weren’t regulations a pain? ➡ Regulations were less complicated than I expected, largely because I'm not working with genetically modified organisms or anything similar. I am sure these vary between countries. ____ What are you doing in your lab? ➡ I’m developing a chemically defined, animal-component free substitute for fetal bovine serum. I’ve achieved some exciting results with a variety of nutritionally demanding primary cell types and will be sharing more soon 🎉 ____ That’s so cool that you built a lab! ➡ Thanks! I'm super excited about it! ____ Happy to answer any other questions - or give advice if you're thinking about doing this too! ____ 👋 I’m building a biotech company and sharing some of the behind-the-scenes online, in the hopes of lowering the barriers to entry for other scientists interested in commercialization.

0 Comments

I’ve spent over 15 years working in mammalian cell culture labs, so a few years ago, I was happy to transition away from the bench to a more management-oriented role.

Being a people manager is a huge responsibility; you inevitably have a massive impact on the lives and careers of your direct reports - for good or for bad. I also gained a lot of satisfaction from assembling the ideal team; one whose individuals’ strengths and weaknesses complimented each other, so they could achieve goals at maximum efficiency. And so, I wondered whether “returning to the bench” as I start my own company might feel monotonous compared to the new challenges around team management I had been enjoying. I shouldn’t have worried. Today, I get a bit of a thrill whenever I enter my lab; I built this lab and I own the IP I’m generating here! It still feels like this crazy dream I’m living and as a result, something as simple as passaging cells feels really cool. __________ Outside of the lab, here’s what I’m learning from building: 1️⃣ Get your webpage up. Someone told me “Get a landing page up early, even if it’s not the most gorgeous landing page, because you’ll learn a lot based on how people interact with it.” So true - and it has been really motivating to get emails from folks from around the world, keen to eliminate their use of FBS. 2️⃣ Build relationships early. I’ve been in the early-stage startup world for a while; it’s a world where research pivots really fast. Those pivots don’t happen so quickly in academic and other industry labs, so it’s been encouraging to realise that I can and should start conversations with collaborators early. 3️⃣ Old habits die hard. Awareness of the traps you’re predisposed to fall into and a team that holds you accountable is critical. Here are some areas I improved in after holding an executive role at a startup company: ➡️ Spending money as needed to reach research goals ➡️ Owning how capable I am ➡️ Saying no Here are the traps I’m continually reminding myself to avoid now that I’m building my own company: ➡️ Being too frugal ➡️ Hesitating to vocalize big goals to others because I feel insecure ➡️ Spreading myself too thin An embarrassing amount of overlap 🙃 Thankfully, being aware of the traps I’m predisposed to fall into means my community knows what to hold me accountable on. With their help, it won’t be those traps that get me! An unexpected joy of lab life: the enthusiasm on my one-year-old son’s face on liquid nitrogen delivery day. Unsurprisingly, breaking down big boxes of consumables is his other favourite way to help me - I’m excited to show him more science as he gets older.

Later, I’ll jump into the lab for a few hours to passage some cells. I’ve been trying to get access to a wide range of new cells lately - to expand the range of primary and immortalised cells that my serum-free media has been used to culture - so there’s a lot of cell culture in my future! I’ll readily admit when I committed to building something new, it felt scary. When people asked what I did for work, I stumbled through my answer. Four months on, it doesn’t feel that way anymore. I have moments where I wish I could do more or move faster (probably the realities of shifting from leading a team of 30 to becoming a one scientist team), but when I take time every month to look at what we’ve accomplished, I’m always pleased with how much happened in 30 days. Microplastics absolutely everywhere - even in the milk we feed our babies!? Some scary science & the startup companies you should be aware of:

➡️ The big issue: Microplastics are tiny plastic particles. At 5-100nm in size, they enter humans by ingestion, inhalation, and dermal contact, but research using animal models and human cell lines suggests they’re also responsible for health problems. 🍼 Science deep-dive: Recently, microplastics were found in breast milk of 26 out of 34 new mothers. No relationship with the use of personal care products containing plastic compounds or consumption of food and drink in plastic packaging was identified, suggesting microplastics are pretty much unavoidable at this point. 👩🏽🔬 Keen to get involved? Startups like Matter. and Xampla (UK), Uluu (AU), and Mushroom Material (NZ) are building in this space by: ✅Removing microplastics from the environment ✅Recycling those microplastics ✅Replacing plastics with sustainable alternatives Viruses that attack bacteria, the immunology of breast milk, and how your DNA remembers fear. A little February round up of the cool science I’ve been digging into this month:

1️⃣ Breast milk has live stem cells in it. When you isolate these cells and expose them to the right nutrients, they can produce milk. This is the basic premise behind some of the early-stage companies centered around laboratory-grown breast milk. These milk-derived stem cells also have unusually low tumorigenic potential and don’t often form teratomas, which could make them great candidates for regenerative therapies. 2️⃣ Phages can be engineered to specifically target and kill cancer cells. Bacteriophages are viruses that infect bacteria, rather than eukaryotic cells like those found in humans. The potential use cases for phages are broad, ranging from human health to agriculture. Use of phages in cancer therapies is still early stage, but there’s a lot to suggest they could become a crucial therapy in years ahead. 3️⃣ Fear triggers epigenetic changes that can persist long-term. Better understanding of these molecular mechanisms could lead to better treatments for post-traumatic stress disorder. It also suggests that certain phobias - spiders, snakes - may be inherited from our ancestors. 1. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6570695/ 2. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10684691/ 3. https://www.nature.com/articles/s41380-024-02453-4 Here’s what I’ve been doing in my lab, plus some interesting science that you probably didn’t know:3/13/2024 14 years ago, the first journal club I ever delivered looked at the effects of culturing cells in serum derived from different animals. These findings have lived rent-free in my mind through subsequent years of working in academic, government, and industry laboratories:

🐭 Mouse cells cultured in human serum had a human-centric immune response. 👵 Human cells cultured in mouse serum had a mouse-centric immune response. …..And isn’t it interesting to consider these results in light of the fact that (all types of) cells are most commonly cultured in serum from foetal cows? 🐮 Like many scientists, I’ve cultured a lot of cells in foetal bovine serum (FBS) because “it works” and “that’s how it's done.” Like many scientists, I could also list the many reasons why FBS is far from ideal scientifically and ethically. In my lab, I’ve been developing an alternative to FBS that supports the growth of the most nutritionally demanding primary cell types. I’m a scientist - so I’m naturally skeptical - but I've gained enough confidence in my results to incorporate a company. Introducing Media City Scientific - That feels really cool. And while it feels strange to be public about this, I’ve benefited massively from working at a hypergrowth startup, watching & learning from the founders. I want to pay that forwards for other scientists thinking about the many directions in which their careers could take them. Who knows, maybe you’ll also find your career circling back to the very first journal club you ever delivered. Today the fibroblasts need passaging. I’m also thawing some muscle cells for a new cell bank and I’m drafting an experimental plan to isolate a third type of cell from breast milk. I only recently learned there are live stem cells in breast milk - isn't science cool!? Given I had a baby less than a year ago, now’s the time to get these cells and bank them for future research!

Over the weekend, I heard good news about being short-listed in an entrepreneurship competition. The final is in four weeks and will be my first time pitching to a broad audience, so I've got a very clear set of experiments to knock over before then - I find these sorts of short-term deadlines really helpful for making sure I'm prioritising correctly. It's been two months since I left my job to focus on building. So much can change in 60 days if you’re dedicated to making a bit of progress everyday - I’m not going to pretend it’s not hard work and that imposter syndrome doesn’t still kick in weekly (at least it's an improvement from daily) but I’m feeling very grateful that I have the opportunity to do this for a little while! Let me tell you about the coolest thing I've ever built: our independent cell culture facility3/3/2024 A massive barrier to entry in biotech is finding lab space to prototype or generate basic proof of concept. You need to keep costs low, but you also need to ensure you retain the rights to the IP (which can be an issue with university labs).

I explored some rental options but each one required significant expense & a commute that would slow down experimentation rates. Then one evening, Christopher Day asked "why can't we just build our own?" So we built our own. It made sense for practical reasons, but let’s be real - it has also been incredibly exciting! Here’s why building was the right choice for me: 1️⃣ I knew exactly what I needed from the second-hand lab equipment market. When I costed out equipment versus renting space for 12 months, the prices lined up. 2️⃣ I already owned the space nearby. 3️⃣ It provides the flexibility to duck in and out every day of the week. Maybe build-your-own isn’t right for you. That's okay - most major cities have rental options, though they can be tricky to find. If you’re in the Sydney area, here are some ideas: (i) I previously worked at a startup company operating out of The Future Project at the Kings School - https://www.kings.edu.au/connecting/the-future-project/ (ii) Another option is yild - https://yild.com.au/ (iii) Co-labs is also reportedly establishing a Sydney presence soon. My previous employer worked with them in Melbourne and they were great - https://colabs.com.au/. ________ Pictured: Today, we have happy mammalian cells growing in antibiotic-free media. 👩🏽🔬 To get there, it took some elbow grease! Learning to dry-wall & cleaning some stainless-steel lab benches 🛠 |

What's been happening?Sharing the Media City journey is important to us because we want to encourage the next generation of scientists to establish companies that will advance scientific research. Check back regularly for the "building in public" updates on what it looks like to establish a scientific company. Archives

June 2024

Categories |

RSS Feed

RSS Feed